On the 23rd of November, an online YPACK consortium meeting was held. In total 25 people from all 21 partners attended the online meeting to share and discuss the progress of the YPACK project.

YPACK updates

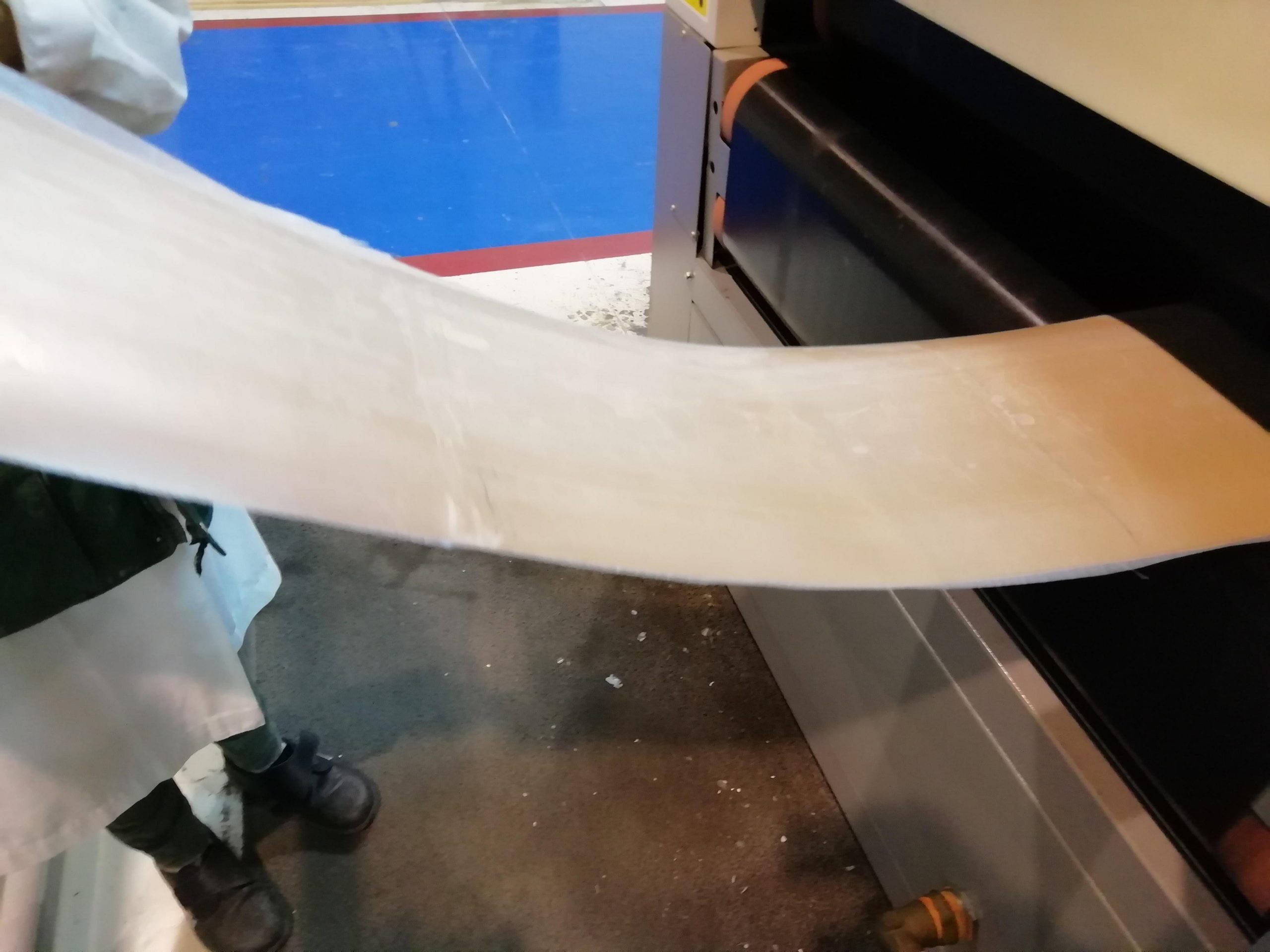

Partners tested a thicker version of the YPACK material which showed promising results and a better resistance during the thermoforming step. Additionally, multilayer trays and films were produced to demonstrate barrier properties. These samples were made by assembling specific layers thanks to thermolamination. In addition, the optimal composition of the different types of trays and films was defined and allergenicity tests proved the safety of the packaging.

Figure 1: Thermolamination step for tray & film (first and third picture) and tray after thermoforming (second picture)

Partners also completed the physic-chemical characterisation of the different YPACK packaging blends and shared with the consortium the results on the antimicrobial properties, migration, material roughness, surface tension, etc.

Furthermore, the latest results on biodegradability in marine and soil environments as well as the Life Cycle Analysis (LCA) were discussed during the meeting. Finally, the consumer science lead at Wageningen University explained the first results of the latest consumer studies organised online, due to the COVID-19 restrictions.

The next steps

The YPACK project was due to end in October 2020, however, the COVID-19 pandemic has caused some delays in the final results. Therefore, the end date of the project has been extended until April 2021. Before then, the YPACK partners will:

- Run last trials to improve packaging thermoforming and sealing.

- Finish packaging characterisation: full mechanical properties, migration, etc.

- End the shelf-life studies.

- Run the final studies on consumer acceptance to see how they interact with the packaging at home and how they understand the waste disposal.