There is an increasing awareness of the need to develop innovative packaging materials that maintain or extend the shelf life of foodstuffs to reduce food waste and minimize the environmental footprint of packaging materials.

The ideal packaging involves lower carbon and water footprints, is biodegradable and/or compostable, makes use of wastes or by-products, is properly eco-designed, safe and has the right preservation properties to minimize food waste.

YPACK, a 3-year EU-funded project will use a holistic approach and methodology involving different knowledge areas to produce the appropriate packaging solution:

Development of packaging solutions (Production of PHBV layers, compounding, prototyping, Industrial Validation)

Product Validation (Quality / Shelf life)

Social approach (Customer profiling, Dissemination, Policies & Regulatory)

Market Assessment (Business study and Risk assessment)

YPACK will scale up production and commercially validate two innovative food packaging solutions based on polyhydroxyalkanoate (PHA). The new packaging will make use of food industry by-products (cheese whey and almond shells), assure the biodegradability, and reduce food waste, in the frame of the EU Circular Economy strategy. A rough estimate shows that an improvement of shelf life by 20% and 50% respectively, has a potential to reduce food waste with 12.5% to 30% respectively.

Specifically, YPACK will develop a:

Fully renewable flow pack film

Fully compostable tray

The validity of these two packaging solutions will be assessed in fresh products (meat, fruits & vegetables and fresh pasta), which are the most significant contributors to food waste. A consumer profiling and market study will be performed to identify consumers ́ preferences and market needs, and match them with the new EU regulations and packaging materials development.

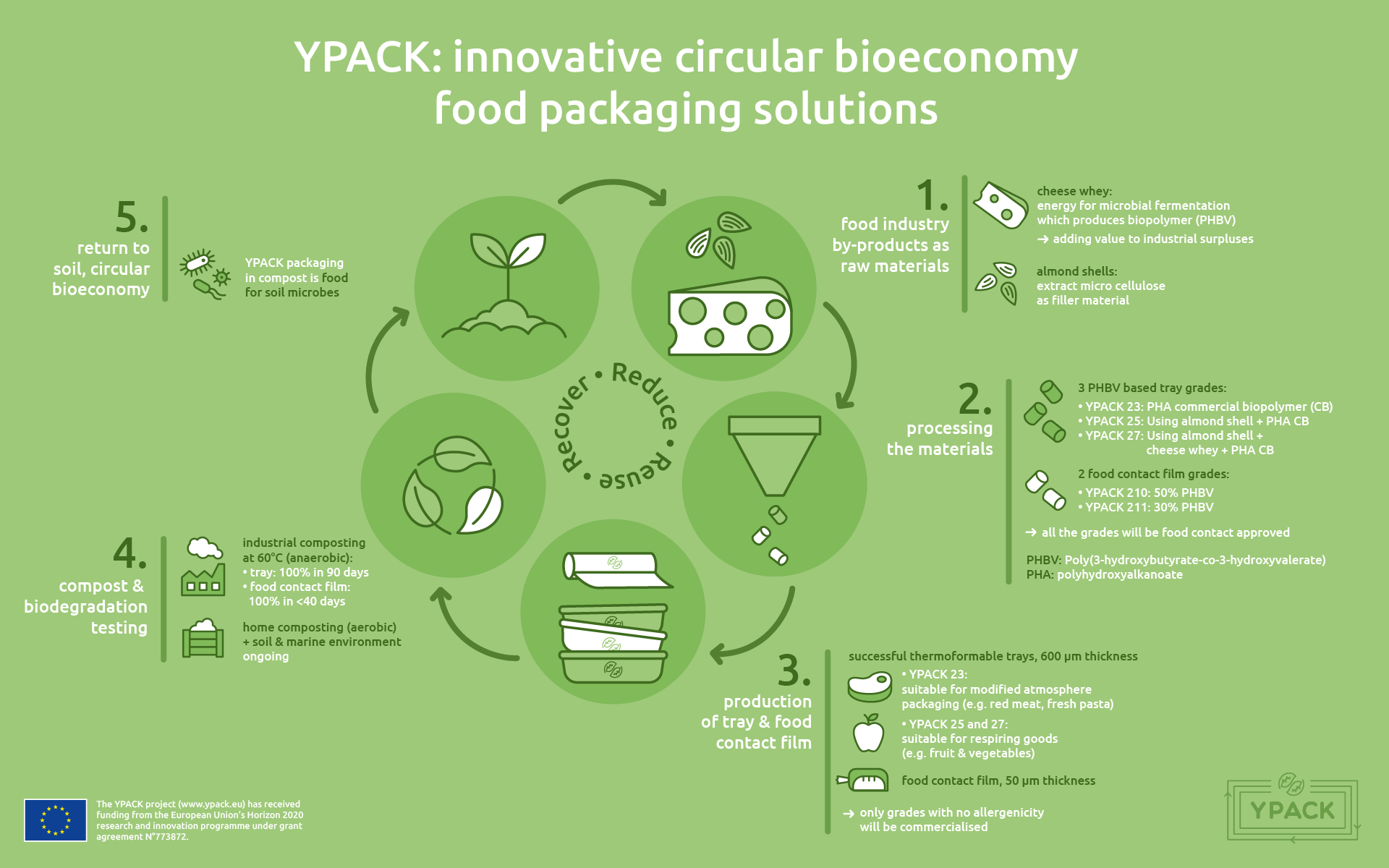

This infographic showcases how the YPACK packaging fits into a circular bioeconomy. We obtain materials from food industry by-products: microcellulose from almond shells, and PHBV biopolymer extracted from cheese whey by microbial fermentation. Using these materials, we create different grades of YPACK material. The YPACK project has developed three trays and two food contact films with different material compositions giving them several food preservation abilities. The packaging can be used for modified atmosphere packaging or respiring goods. Due to the biodegradability grade of PHBV, the YPACK packaging can be composted in industrial conditions (60°C, anaerobic) in 90 days, but the YPACK team has also seen promising results for home composting as well as biodegradation in soil and marine environment. In the end, the biodegraded YPACK packaging is food for soil microbes that could, who knows, later be used for microbial fermentation, and produce PHBV again…

A consumer profiling and market study will be performed at the first stage of the project in order to identify consumers´ preferences, market needs and match them with the new EU regulations and packaging materials breakthroughs. Furthermore, a market assessment will be conducted to asses the exploitation strategy and the business plan development

WP1 – End users’ specs and product design: identify market failures or cultural or behavioural barriers to overcome (industries and consumers), aspects for customer’s perception and acceptance, gender aspects…

WP6 – Innovation management: IPR and exploitation strategy, business plan development, contribution to standardization.

Several processes related to the production of multilayered systems will be optimised and scaled up to a pre-industrial size to validate the production of the proposed packaging solutions for extend the shelf life of selected food products.

WP2 – Optimise raw materials and process optimization as well as the production and selection of appropriate substances (natural extracts and inorganic nanoparticles). Incorporate the use of raw materials and active substances and pilot plant prototyping of trays and flow pack.

WP3 – Scale up process and develop pilot lines: preindustrial scaled up of processes and production of trays and flow pack.

WP4 – Product validation: evaluation of packaging convenience, consumers’ acceptance at sales points, shelf life assessment of food products and final techno-economic analysis of packaging.

WP5 – Characterisation, safety studies and LCA: characterization support for products and materials related to WP2 and WP3, including overall and specific migration tests, risk assessment of developed packaging solutions and LCA.

EUFIC will lead communication activities with WP 7 and give support in product specifications definition and design.

Project technical details

Start date: 1 November 2017

Duration: 3 years

Call: H2020-SFS-2017-1

Coordinator: CSIC-IATA (Instituto de Agroquimica Y Tecnologia de Alimentos), Spain